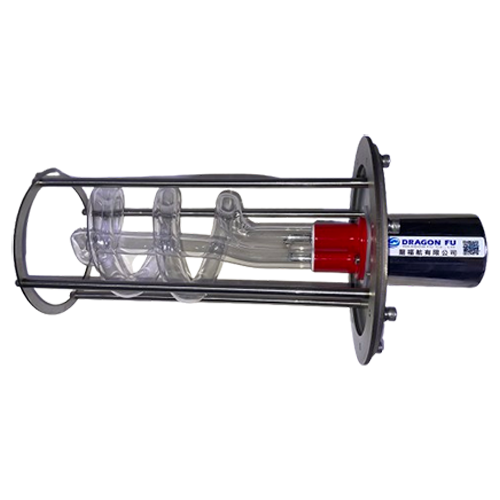

Built-in - Ultraviolet UVC Sugar Liquid Sterilization

Built-in - Ultraviolet UVC Sugar Liquid Sterilization

-

Ultraviolet purification is an effective method for controlling microbial contamination in the liquid sugar manufacturing industry. It provides an environmentally friendly solution without chemicals to sterilize processing water and liquid syrups, and improves product quality. The advantages of ultraviolet treatment include cost-effectiveness, ease of use, safety, and extended shelf life.

The liquid sugar processing industry is facing increasing pressure to meet strict quality standards in this rule- and safety-oriented market. Although the high osmotic pressure in syrups limits the growth and reproduction of microorganisms, some microorganisms can still survive in spore form. The consequences are discoloration of food, shortened shelf life of carbohydrate products, and increased risk of infection. As the demand for chemicals and preservatives decreases, the contamination issue becomes even more serious.

Ultraviolet purification is very effective. It can eliminate bacteria, viruses, and other microorganisms, quickly processing liquids using ultraviolet sterilization systems.

Chemical-free: Unlike other chemical methods, ultraviolet treatment uses only light, making it a safe, chemical-free alternative.

Eco-friendly: Ultraviolet purification does not produce harmful by-products and leaves no residual substances in the treated liquid.

Easy to implement: The installation and maintenance of ultraviolet treatment systems are relatively simple, requiring minimal training for operators.

Versatile applications: Ultraviolet treatment is applicable in various fields, such as water treatment, air purification, surface treatment, and various food and beverage processing.

Cost-effective: The cost of ultraviolet purification is lower than other methods, especially in terms of ongoing operational costs.

Safe: Ultraviolet treatment systems do not pose health or safety hazards to operators. This makes them a safe choice for use in various environments.

Water Treatment:Process water is a crucial component in the production of liquid sugar, and it is essential to ensure that it is free from harmful bacteria, viruses, and other microorganisms. Ultraviolet treatment can remove contaminants that may exist in process water. It ensures that the water used in the production of liquid sugar is of the highest quality.

Syrup Disinfection:Liquid syrup is highly susceptible to contamination by bacteria and fungi, leading to spoilage and a reduced shelf life. Ultraviolet purification can sterilize the syrup, eliminating harmful microorganisms and ensuring that the syrup is free of toxins.

Quality Control:Controlling the quality of syrup is crucial during the production of liquid sugar. This is a necessary condition to ensure that it meets the expected quality standards. Ultraviolet treatment can serve as a quality control tool, as it is an effective means of eliminating harmful microorganisms. Controlling the quality of syrup is crucial during the production of liquid sugar. This is a necessary condition to ensure that it meets the expected quality standards. Ultraviolet treatment can serve as a quality control tool, as it is an effective means of eliminating harmful microorganisms.

Extended Shelf Life Quality Control:Controlling the quality of syrup is crucial during the production of liquid sugar. This is a necessary condition to ensure that it meets the expected quality standards. Ultraviolet treatment can serve as a quality control tool, as it is an effective means of eliminating harmful microorganisms. The growth of bacteria, yeast, and mold can spoil liquid syrup. Ultraviolet purification can eliminate these microorganisms, effectively extending the shelf life of the product while reducing the risk of spoilage.

Improved Safety:The presence of harmful microorganisms in liquid syrup poses a serious health threat to consumers. Ultraviolet treatment can eliminate harmful microorganisms, ensuring that the product is safe for consumption and reducing risks.